Wednesday, 20 September 2017 News Articles

Tank Tops

Plastic has been fantastic for Promax, with 25 years of tank manufacturing, from water and milk transport, to firefighting and dust suppression.

IF NECESSITY IS THE MOTHER OF ALL INVENTIONS, attribute Promax’s range of polyethylene water tanks to an idea Tim Strachan had back in 1992. Working as a self-employed WE CAN engineer at the time, Tim researched and discovered demand for plastic water storage tanks, and looking for a challenge of manufacturing and distributing nationally he set about a new business venture of rotational moulding plastic tanks. Originally designing and building water storage tanks for homes and farms, Tim opened his first factory in Whangarei in 1995.

When his sons Hamish and Walter joined the operation in the late-2000s, Tim was able to plan his next expansion and by 2007 had achieved his original vision of North and South Island plants supplying customers nationwide.

By 2010, Promax had outgrown its Whangarei factory, and with the business going strong they built a purpose-built factory and head office in Kerikeri. Promax is now the manufacturer of NZ’s largest range of water management solutions. In 2016 Promax also produced the largest single piece plastic tank in NZ, with a capacity of 50,000 litres!

Now 69, Tim has taken a step back to an advising role and Promax is run by Hamish and Walter. Over the past five years, Promax has recognised demand for tanks for transporting liquids. Originally a supplier for just the tanks, Promax has now evolved - thanks to Tim’s engineering background - into working closely with customers to produce complete tanker solutions. Promax can now help build the complete package including pumps, sprayers and hoses for a turn-key drive-away package.

Promax Transport Tanks are all made from Polyethylene, a light, strong and durable alternative to steel or fibreglass and have the benefit of being a lot more flexible and lightweight. Its range now has more than 40 sizes ranging from 20 to 30,000 litres.

Promax’s poly tanks have a wide range of uses and are UV-stabilised to withstand the rigours of NZ’s climate. They are suitable for many liquids including water, milk, leachate and for heavier fluids such as molasses and fertilisers up to 1.8SG.

As the tanks are classified as a load, securing the load is very simple by using the integrated tank pin mounting kits available for flat deck or skid-mounting.

As the tanks are classified as a load, securing the load is very simple by using the integrated tank pin mounting kits available for flat deck or skid-mounting.

Steel Skid frames for Transport Tanks allow simple installation and ensure the tanks can be mounted on any truck. The hot-dip galvanised frames have forklift points for easy mounting and dismounting when the tank is empty and comes with the optional extension plate for mounting pumps and spray bars.

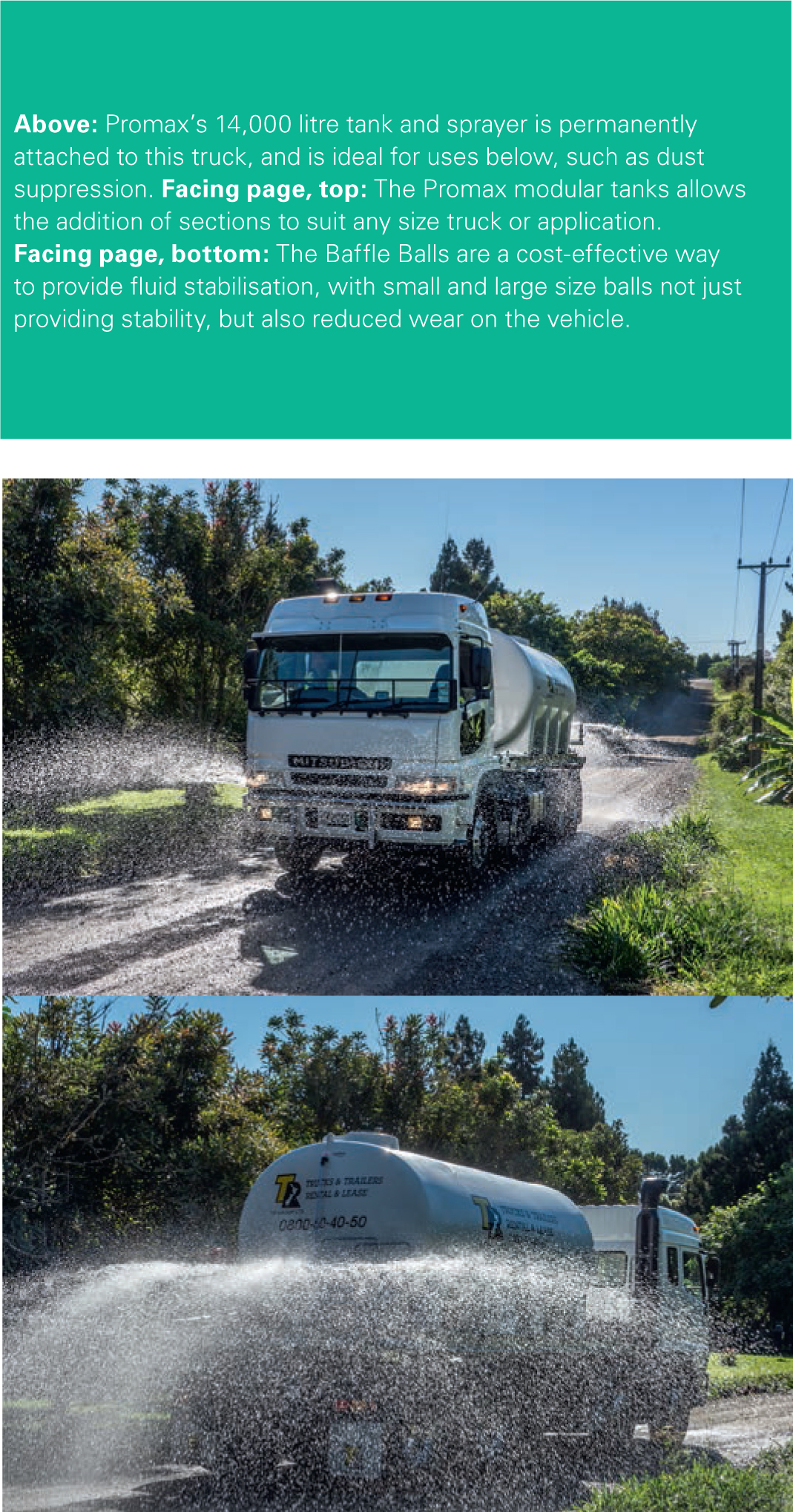

Promax’s Dust Suppression Spray System is used to wet down construction sites, road works, quarries and mining sites, and the unit attaches to all Promax Free-Standing Liquid Transport Tanks. Promax has basic Dust Suppression models available or can customise to individual requirements. Easy to operate, the truck-mounted spray system is galvanised for durability and available with in-cab remote control.

Water Delivery Units are particularly popular during summer, using the same food-grade manufacturing materials, and these can be easily fitted – and removed – to flat deck trucks, making a vehicle very versatile without tying up capital in a complete new vehicle.

Available as an option across most Transport Tanks, the Promax Ball Baffles are made of food-grade material and come in two different sizes. The low-displacement balls simply drop into the tank to act as liquid movement suppressant, stabilising the load, reducing surge, increasing vehicle stability, and improving braking distance and cornering to the point of reduced wear on the vehicle. One small 195mm ball is recommended per seven-litres of fluid, while the larger 355mm ball is recommended every 40 litres.

Available as an option across most Transport Tanks, the Promax Ball Baffles are made of food-grade material and come in two different sizes. The low-displacement balls simply drop into the tank to act as liquid movement suppressant, stabilising the load, reducing surge, increasing vehicle stability, and improving braking distance and cornering to the point of reduced wear on the vehicle. One small 195mm ball is recommended per seven-litres of fluid, while the larger 355mm ball is recommended every 40 litres.

“Take a 10,000 litre tank, which is probably our most popular size as it fits on a 6x4, it works out to be around 10-11 tonnes payload and is ideal for dust suppression or water cartage,” explains Hamish. “You divide 10,000 by 40 and you have 250 balls placed in the tank that form a honeycomb throughout the liquid – which is where you get all the movement. It’s a proven anti-rollover design.”

The Modular Tank System offers flexibility and economy for transporting bulk liquids. Exclusive use of polyethylene eliminates rust issues and reduces weight, allowing for increased payloads. Mounted with the secure pin-mounting system, the tank sections can be drained individually allowing for cartage of different liquids, or linked to allow for equalised filling. The tanks are fully baffled longitudinally and latitudinally for stability and reduced wear. And being modular, it’s expandable for different sizes of trucks and trailers.

Just five years down, the Transport Tank side of the business has really evolved and from its stand-alone tanks to a full drive-in drive-out setup, Promax can also consult regarding building a custom Transport Tank unit. Promax has come a long way in 25 years, but there’s still clearly plenty left in its tank.